Clutch Install Problems

Short Version:

1979 CJ5 with t18 trans had its clutch replaced by myself, a rookie mechanic. After putting it all back together, I go to start it, and my clutch is making a HORRIBLE screetching sound, after a second or two the screetching stops and everything seems "ok," however I can not put it in gear at all.

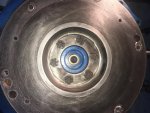

I Installed the appropriate LUK clutch kit, which included new pilot bearing and throw-out bearing(which i greased). I kept the original flywheel as it was in good shape to my eyes.

Also,

The jeep shifts perfect when the engine is off. I tried starting the jeep in neutral with the clutch pedal depressed and the sound was significantly worse. I put the jeep in 1st gear, engine off, and held down the pedal on start-up and it lurched forward.

I was thinking my mistake was maybe installing the friction plate backwards but thats not possible. I just picked up a second LUK kit to see if it was reasonable that I had installed it backwards... but no, it would've been impossible to snug the blots to the flywheel given the springs and bumpout in the friction plate...Also I took extreme care to not do that mistake upon install.

ANY help would be very much appreciated. I also tightened everything to factory specs and it all went back together smoothly. Im miffed.

1979 CJ5 with t18 trans had its clutch replaced by myself, a rookie mechanic. After putting it all back together, I go to start it, and my clutch is making a HORRIBLE screetching sound, after a second or two the screetching stops and everything seems "ok," however I can not put it in gear at all.

I Installed the appropriate LUK clutch kit, which included new pilot bearing and throw-out bearing(which i greased). I kept the original flywheel as it was in good shape to my eyes.

Also,

The jeep shifts perfect when the engine is off. I tried starting the jeep in neutral with the clutch pedal depressed and the sound was significantly worse. I put the jeep in 1st gear, engine off, and held down the pedal on start-up and it lurched forward.

I was thinking my mistake was maybe installing the friction plate backwards but thats not possible. I just picked up a second LUK kit to see if it was reasonable that I had installed it backwards... but no, it would've been impossible to snug the blots to the flywheel given the springs and bumpout in the friction plate...Also I took extreme care to not do that mistake upon install.

ANY help would be very much appreciated. I also tightened everything to factory specs and it all went back together smoothly. Im miffed.