Trans AX15 Alignment

aglinks

Active Jeeper

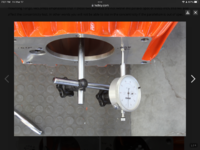

Has anyone figured out how to measure the concentricity of an AX15 bellhousing? I have an Advance Adapters AX15 with their install kit behind my 4.8L Vortec and it keeps eating pilot bushings. I have sent a couple emails to Advance Adapters but received no response, so I’m hoping I can find a way to measure how far out of alignment it is and just order new offset dowels for the engine.